Injection molding simplifies the manufacturing process, and it makes it easier to produce parts with advanced complexities, offers an alternative way to produce high-quality products at a cheaper cost, and offers incredible flexibility when it comes to the use of materials and colors. All of these advantages have made it one of the most popular manufacturing processes in the world, and a much better number speaks for themselves.

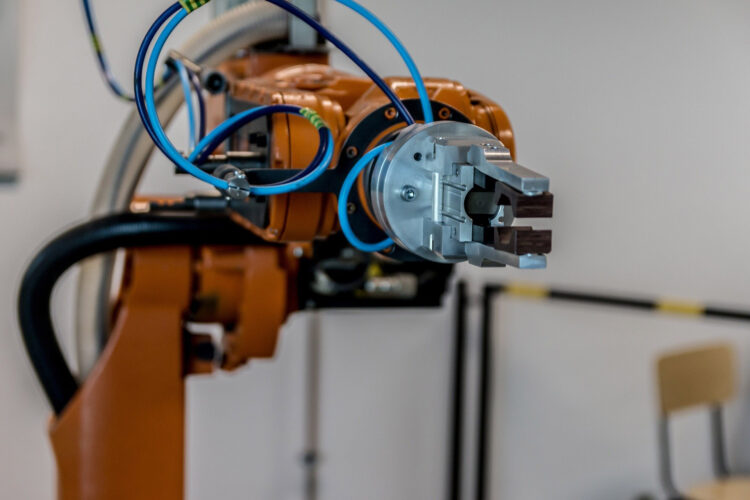

What is even better is the fact that by opting to automate the molding process with injection molding robots, one can easily maximize the benefits of this technique while also limiting its downsides. The following are the different ways in which adopting injection molding automation as a central manufacturing process can improve the productivity of your employees, reduce their responsibilities while speeding up the whole process. There are many reasons and ways on how and why deploying injection molding robots improves employee productivity, but in this article, we present you with the three most beneficial reasons. There are many ways that robots can help, and for those who want more info on that topic, click here, and find out everything there is on productivity and quality that comes with deploying injection molding robots.

1. Freedom to do meaningful wor

Tasks like loading plastic pellets into the barrel, moving raw materials from one end of the factory to the next, checking the heating conditions, and monitoring for malfunctions can be routine and soul-sucking. No one likes to do this job as it takes too much time. When employees do this work day-in-and-day-out, they tend to become bored and lose interest. And when this happens, it can be a drain on their morale as workers became less interested in the job, which, in the end, reduces productivity. It is something that will eventually also affect their positive attitude towards work.

And, here we come to the solution as you can save your employees from the pain of doing repetitive and monotonous tasks by relieving them from those responsibilities and letting robots handle these tasks. As another benefit, robots can do this work faster and more accurately, which also affects the costs and reduce the expenses. Doing this will then free up your employees to do other tasks that are less mundane and which have a direct impact on the company’s wellbeing. By doing work that gets them excited, your employees will then be able to perform at a higher level. Employees morale plays a significant role in every company, as everyone wants to be happy when they go to work, and an employer wants motivated and workers that are eager to work.

2. Injury-free employees are more productive

Injury is something that everyone wants to avoid, but no matter how great of precaution, there is always a risk of getting injured while on the job. That risk considerably increases when the people work with the machines that represent a great treat, as the chances for injury are much higher.

The injection molding process typically exposes employees to a number of hazards. Employees who are feeding plastic pellets into the barrel are faced with the risk of falling from their ladders. Those whose work is to carry out purges are exposed to the risk of getting burned in cases where splashes occur. And since the main machine and other auxiliary machines have moving parts, employees who come into contact with these machines are under the constant risk of getting crushed or losing parts of their limbs. This list of possible injuries only gets larger.

When accidents happen, they not only affect the employee that got hurt but also leave other employees traumatized psychologically. Employees who are injured cannot do their work as productively because they may be in pain or may have physical or psychological limitations due to the accidents. All of these things have a negative effect on the overall productivity of employees.

Automation lowers the risks of injuries. It limits employees’ exposure to traumatizing events simply because robots can be assigned to do all the dangerous tasks. Furthermore, since employees do not have to do those tasks that make them extra cautious, they can be able to work faster and in a more relaxed state, something that usually goes a long way towards improving productivity. That combination of motivated and relaxed workers is something every employer wants and needs.

3. Robots work faster and longer

Automatization is pretty significant as collaborative robots are designed to work alongside human beings. As a result, they do not have to do all the work, and can only handle aspects of a task (those with greater risk, boring ones, those who would take too much time for human, etc.), and then let an employee complete the other half of the task. Aspects of the molding process encourage collaboration between robots and machines with the aim of guaranteeing better efficiency, accuracy, and reliability. Furthermore, since they can work for longer, and since they can work faster than human beings, they can do the tedious and cumbersome portion of a task beforehand. But this does not mean that the people are not needed in the process, as they represent a much valuable asset, and the only goal should be regarding their motivation by meeting their needs.

An excellent example of a collaborative task is the quality control stage of the process. Instead of letting people go through all the products in order to weed out those with flaws, you can have the robot do the sorting based on different degrees of quality. Then, a human worker can examine and analyze the products based on the sorting previously done by the robots. But being able to do that only comes with experience, and people simply can make much better decisions when it comes to this, but relieving them from all the work, also increases productivity. As a result, using a robot to do the initial sorting will make the employee more productive and his or her conclusions more reliable simply because they did not have to go through all the products. The automatic sorting that was done by the robot made their work more straightforward, and at the end of the day, everyone is happy with the job well done.