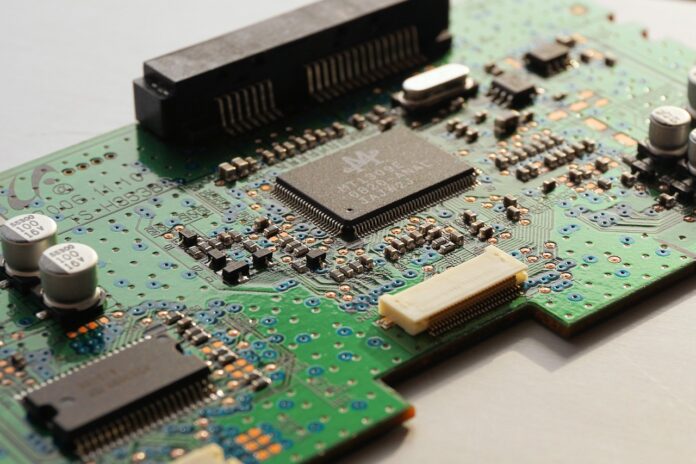

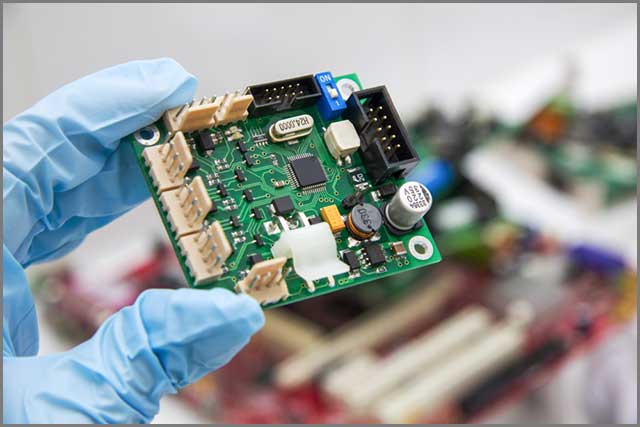

Printed circuit boards are much needed in today’s modern society. Almost every device that we use nowadays has a printed circuit board that allows us to use all of the functions on it. A lot of businesses, startups mostly, need printed circuit boards for their application, but they don’t need a large number of them. In such scenarios, low-volume PCB or also known as low-volume printed circuit board assembly process is used.

By using this process not only you get to save money but you also end up with circuit boards of higher quality. It’s quite obvious that the fewer products are manufactured, the higher the attention to detail is. And, in the world of electronics, quality circuit boards are basically everything.

In today’s article, we’ll talk about this low-volume PCB assembly process and we’ll help you learn more about it. So, if you are interested, feel free to stick with us until the end. Let’s take a look.

1. Due to the smaller volume, the PCB’s will have a better quality

This is a fact about the low-volume PCB assembly process itself, and it’s pretty encouraging since everyone is looking for quality over quantity, especially in electronics. With low-volume production, all of the boards will go through a lot more testing which is not possible when you need hundreds of thousands of them being made. But, this is not the only benefit. There are many others to be listed, but before we get into it we want to point you into the right direction in terms of research. For additional information check what experts from pcbonline.com have to say about this.

Now let’s take a look at the other advantages low-volume production can bring when it comes to the much-required printed circuit boards.

2. You have a lot more room for design changes

Mass-production of printed circuit boards is like locking your design and pulling the trigger, enabling market circulation and a permanent “stamp” for your product. Once you do this there’s no going back, meaning if your design has flaws, your reputation as a brand will suffer.

The low-volume PCB assembly process is great because it allows you to test things out, but not with only one prototype. You produce a smaller amount of boards that can still be used in your real products, except you can find out whether you need changes or not without damaging your reputation in case you do need to improve something.

Even if you don’t end up sending your product on the market upon doing mass production, you still end up with flawed printed circuit boards which means you’ve wasted money for nothing. So, cost control is very important, and low-volume assembly allows you to keep your finances in check.

3. DFM vs DFT – Differences and explanation

These letters may confuse someone who isn’t familiar with low-volume PCB assembly, but we’re here to explain so just sit back and relax.

DFM stands for Design for Manufacturing. This is a process of optimization and the end goal is to keep the PCB design free of errors. DFM can then be divided into two different groups, DFF and DFA.

DFF stands for Design for Fabrication and takes care of all the flaws, obstacles and overall issues that have something to do with the manufacturing.

DFA on the other hand stands for Design for Assembly and focuses on solving problems that the engineers experienced in terms of design.

As for DFT, it stands for Design for Testing, and it’s also of huge importance. The goal here is to perfect your PCB design so it can withstand all the tests you throw at it during the testing phase. Some popular testing methods are X-ray inspections, electrical testing and a visual check as well.

In DFT, there are also two different approaches. Design for In-Circuit Testing and Design for Functionality Testing.

4. Choosing the right manufacturer for the assembly

No matter what it is that you want to be manufactured, you need to choose a reliable and reputable manufacturer that can finish the task flawlessly. Here are some of the things that you should look for when trying to find a low-volume PCB assembly manufacturer:

– Previous experiences

– Years of work and many successful projects under their belt

– Competitive price compare to other offers on the market

– No communication obstacles

– They don’t care whether you only need fifty boards or a thousand

– Freedom to choose and customize your order as much as you need

These things are not easy to find but if you do manage to notice them in a manufacturer you’re eyeing out, we can safely say that you’re headed in the right direction.

5. You should almost always consider Low Volume PCB assembly

No matter how confident you are in your upcoming product, the most important thing has always been testing, and it will remain that way for many years to come. You may think that this is just an extra layer of costs and that you’re ready for mass production, but the small price you pay for being sure about the quality of your product can be extremely small compared to what you could be losing if you release a faulty product.

Keep in mind that this is the world of electronics, and things sometimes stop working unexpectedly. You don’t want your few thousand circuit boards failing don’t you? This is why you need to test things in smaller quantities, and that’s where low-volume PCB assembly starts to shine.

Conclusion

There are numerous advantages of low volume PCB assembly that you should know about, the main one being saving a lot of money which is pretty crucial for the success of every business in these modern times. In today’s article we covered everything you need to know about this assembly process so feel free to check the content out and thank you for staying with us until the end.