It is crazy to think about the fair just how far laser engraving has come. What was once an expensive machine that cost several thousand dollars can now be bought for a few hundred dollars on websites such as Amazon or eBay. With a click of a button, you could get the device sent to your home that can engrave any kind of material. Going back 10 years ago, this was not possible at all. But, is it that easy to use a fiber laser marking machine?

Well, just because these types of products are now accessible to the general public, does not mean that using them is easier or simpler. They still require you to have a little bit of knowledge or at least some experience to ensure that the engraving process will go smoothly. But, there is no need for you to worry because there is not a lot you need to learn. Of course, this only applies to cheaper and simpler engravers.

Much larger and industrial machines require both a lot of knowledge and experience to maneuver them. Fortunately for you, we are not talking about them.

This is the reason that I decided to write this step-by-step guide for 2024 and help people learn how to use laser cutters.

Pick the right material

Before you do anything, you will need to decide on what kind of material you will be working on. It is very important to understand that every material has its own resistance and properties. So, if one type of laser works on a certain material, it might not work on a different one.

For example, metals are usually much stronger, sturdier, and harder than most plastics. So, if your machine can make markings on a plastic object, it might not be able to work on metal objects.

This is why it is so important to do a little bit of research on the machine to determine whether it will be able to work on that certain material that you plan on using.

Fiber laser works best on metals

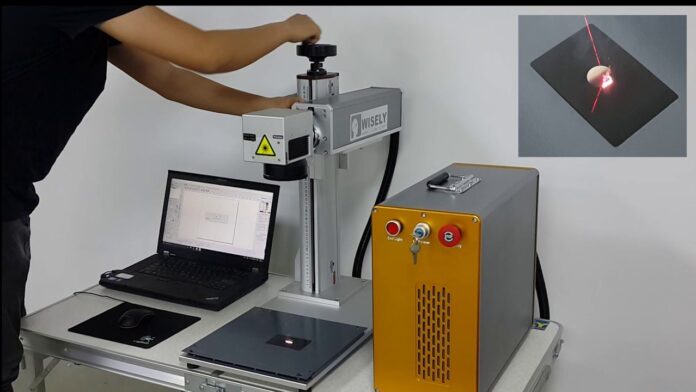

After reading through my previous paragraph, I assume that you have started thinking about what kind of materials you are going to use. If you plan on using metal, you should probably go with a machine that uses a fiber laser. The optical fiber in this device is more than capable to engrave most metals. Although, those that are a bit sturdier might require something a little bit more powerful.

Understand that the laser is dangerous

Since you plan on using this type of device, it is essential that you first learn and understand how it works. And by that, I mean understanding the dangers of using it.

Considering the fact that the laser inside is able to engrave tough materials such as stainless steel, it makes sense that it would be able to hurt human flesh. Your skin and everyone else’s is much weaker and susceptible to damage from a laser. For example, the Desktop Mopa laser marker which you can find on hispeedlaser.com has a power of around 30 watts. This might not seem like a lot of power to you, but it can still be harmful.

This is why most of these cutters come with a protective cover that is put on top to ensure that the laser does not escape the cutting area.

However, I do not believe that is enough. You should also implement a habit of using protective equipment. Protective glasses and gloves should be essential every time you plan on using this device. Whatever you do, make sure you the light amplification by stimulated emission of radiation never points in your eyes.

Machine maintenance

Most people think that a device such as this one would not require any kind of serious care or maintenance. But, that is simply not true because it deserved maintenance just like any other device that involves cutting, engraving, or marking.

All that dust and those tiny particles from the material you have been cutting can end up in every nook and cranny. If you do not clean up that dirt once in a while, it might accumulate too much and render the device useless.

Assuming that you do not want to spend money on buying replacement parts, I would recommend that you do your maintenance at least once a week. Although, it depends on how much you are going to use it. If you just work on one project a week or month, you should probably clean just once or twice a year.

The optics require special care

The most expensive and vital part of every laser cutter is the optics. Light cannot be focused enough without optics to leave a mark on the material. So, if you do not tend to the optics properly, they might start deteriorating over time making your machine useless for etching.

What can you do? Well, you should clean them after several uses, but you should also be very careful with them. When handling the optical lenses, make sure you do not throw around. They are very delicate and the lens can break very easily. Once it breaks, there is no fixing it.

Also, when cleaning it, make sure you use a microfiber cloth and nothing else. It does not need chemicals or water. Both of these can cause serious damage to the glass on the lens. The microfiber cloth is smooth and soft enough that it will not any kind of scratches.

Keep the lens in their protective case

When buying a fiber laser marking machine, the optical lenses usually come in their own protective case to ensure that they are not damaged during shipping. I suggest that you build that habit of using this protective case every time you can. Instead of leaving the optics inside of the device, you should take it out and put it back in that case.

As you can see, it is not that scary or difficult to use your fiber laser marking machine. With this guide, you will be able to handle it quite easily.