When it comes to manufacturing printed circuit boards or PCB, the design is everything. If it isn’t planned in great detail, the chances are that the final product won’t be of the highest quality, meaning that it will be likely to fail.

Nowadays, this task is even more challenging simply because these boards more complex and, at the same time, compact. It is crucial to plan this design carefully in order to avoid any potential functionality issues in the future. In the following article, we will introduce you to the things that have to be considered while completing this task.

Environmental factors

Without a doubt, elemental factors are the most common source of problems and failures. Due to this reason, manufacturers have to take into consideration the environment in which the board will operate. Naturally, this is something that completely depends on the final product, but here are some of the most frequent factors.

Heat

Obviously, the first thing that has to be considered is the heat. When it operates, the board will heat up on its own. Generally speaking, this shouldn’t be an issue. However, if it will be exposed to outdoor temperatures or direct sunlight, the materials and joints will likely suffer. Similarly, it is important to think whether the board will be installed in close vicinity of some other operating item that will also produce heat. It is why manufacturers have to put their printed circuit board through an extensive testing process, and you can learn more about it on www.uetpcb.com. It goes without saying that if they notice some malfunctions and potential issues, they can do redo their entire design of the item or add some additional components to prevent these from occurring and increase the quality and lifespan of the board.

Moisture

Right next to the temperature and heat factor, humidity is the next thing that has to be considered. We can all agree that moisture is the number one enemy of all electronic devices. It is something that can destroy them over a short period of time. Since a printed circuit board is an essential part, manufacturers need to make sure that it is built correctly so that it can withstand the negative effects of moisture. This is especially important if the item will be placed and managed in an environment where temperature changes drastically over a short period of time. There are several moisture protection methods, and tricks companies use to ensure the resisting power of their products.

Dust

Oftentimes, it doesn’t matter how carefully people maintain their electronics because dust is a thing that they cannot completely eliminate. It is just a vicious circle we are all trapped in. Even though we clean our electronics regularly, dust still accumulates, so we have to do it all over again.

Manufacturers completely understand this problem, so they either include the appropriate Ingress Protection rating into the enclosure or use specific components that can withstand a certain amount of dust. Naturally, before choosing a method to implement, they have to think about the setting where the item will be located because, in some places, the dust accumulates faster. Similarly, they have to think about the electronic device itself since some of them cannot be easily and regularly cleaned due to the access restrictions.

Vibrations

The final thing that companies have to consider is how the whole device operates. Is it fixed to a certain place or not? Can people move it around? Does it produce vibrations? Yes, these can also be noted as environmental factors. It is why manufacturers have to use components that will boost the board’s strength and durability. Clearly, these have to be chosen according to the mechanical properties of the item so that they don’t interfere with its functionality.

What’s more, manufacturers also have to consider transportation. How will these boards be handled? What is the best way to protect them from accidental damage? As you know, vibrations occur during transportation, which is why every component must be tested in the lab prior to manufacturing. This is the only way for professionals to see if there are some weak points in their design that have to be upgraded to ensure safe delivery to their clients.

Other factors to be considered

Now that we have introduced you to environmental factors, we will discuss some other things that have to be taken into consideration. First of all, there is the material that is used in building these components. Every company’s main goal is to meet its customers’ requirement, and there is not a single person in the world that wants to purchase a product that is made of low-quality materials. Why? Well, simply because these devices don’t have a long lifespan, meaning that they will likely fail soon, or on the other hand, can be easily damaged.

Similarly, there is also the matter of specific components. Sure, these will deteriorate over time and eventually fail. However, this cannot happen during the expected lifespan of the device. The only way to ensure that this doesn’t happen is to choose components that have been thoroughly tested, and that can withstand all of the above-mentioned environmental effects.

Furthermore, the entire manufacturing process must be taken into consideration. Why? Well, because most of the failures occur due to the defects that happen during this process. Yes, as already stated, materials and components play a significant role, but a malfunction can also occur due to the board contamination and the lack of surface finishing and protective coat.

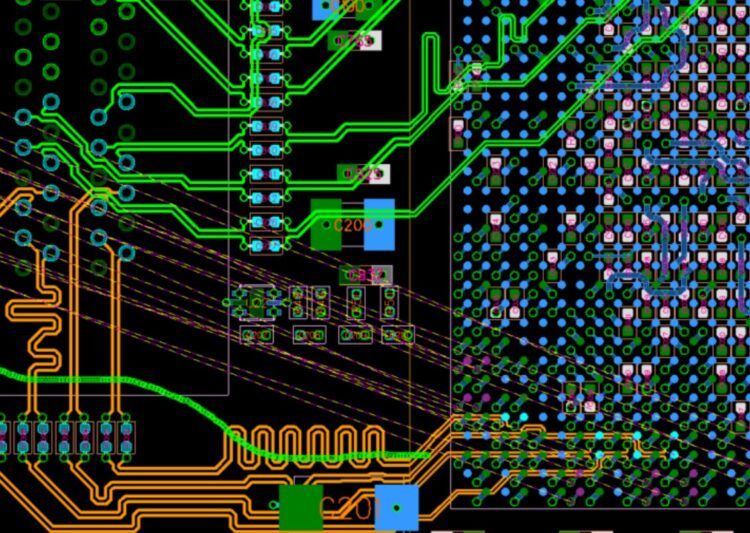

Finally, there is the matter of the overall design of the printed circuit board and the layout of all components. These boards include multiple parts, and it is crucial to be certain that all of them are assembled correctly and that they are fully functional. Due to this reason, professionals need to make a detailed plan before starting the actual work on building a printed circuit board. As already stated, every design is tested before it goes through the mass manufacturing process.