Different machines are involved in industrial processes. The construction, use, and maintenance of these machines depend on the industry in which they are used. While some are specifically meant for certain industries, machines can be used for different purposes and in different industries. One of the common machines is the shot blaster equipment. Shot blasting is a commonly used method of surface cleaning in industrial applications. It involves propelling blast media, metal shots, at the surface to be cleaned. In most cases, shot blasting is used to clean metal surfaces. Other than cleaning, shot blasting can be used to strengthen and test the performance of surfaces. More information about shot blaster equipment, check out PANGBORN.

Types of Shot Blaster Equipment

There are different types of shot blaster equipment you can choose from. Your choice of equipment depends on what you want to achieve and the material you deal with. Shot blaster equipment are classified depending on how the abrasive materials are propelled onto the surface. They include;

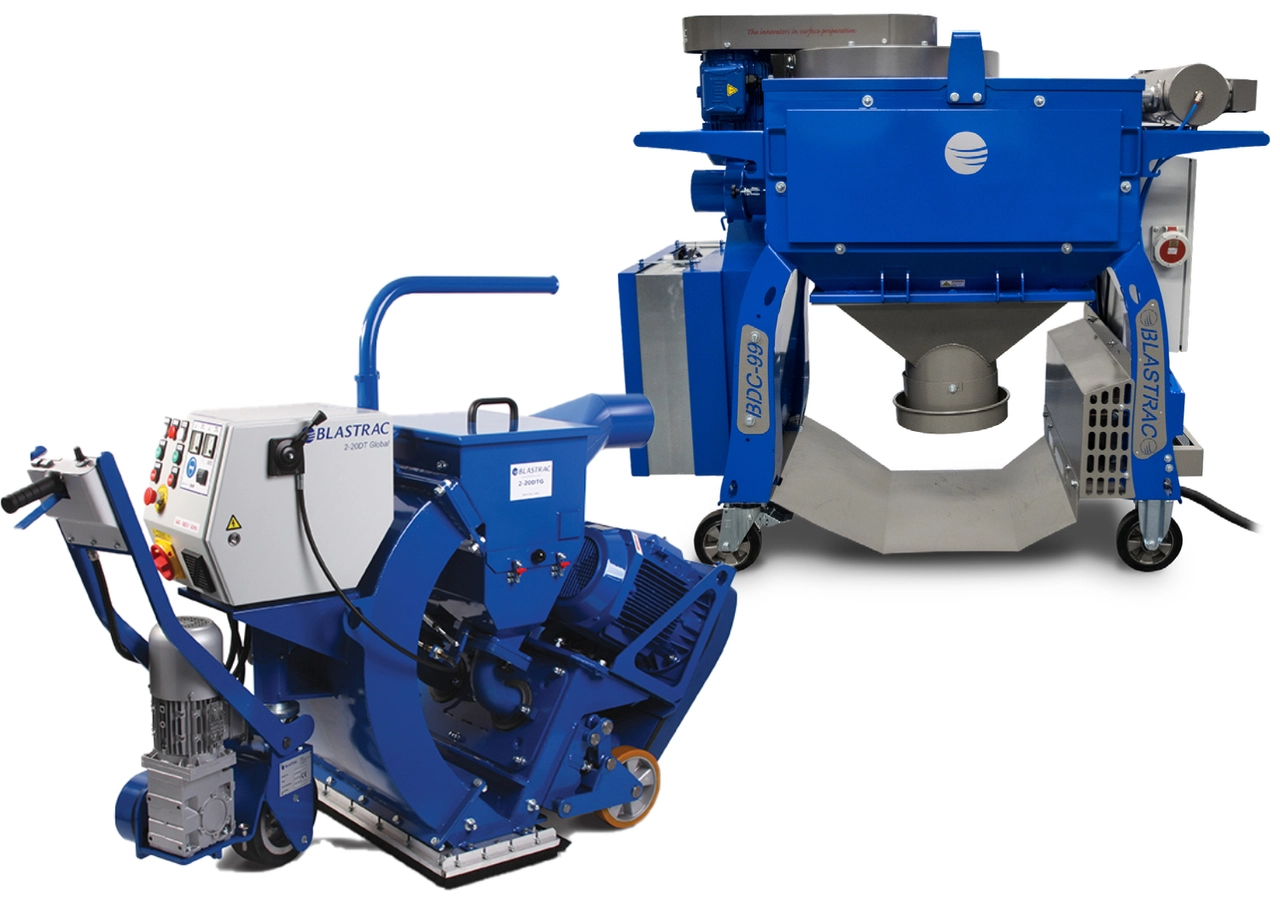

- Wheel blasting equipment – This kind of shot blaster equipment uses a centrifugal blast wheel to propel the metal shots onto the surface being worked on. The centrifugal wheel provides a force that evenly distributes the metal shots over a surface being worked on. The wheel is driven by motors connected to it with belts. The speed of the wheel is adjusted by regulating motor rotations. This is done to achieve different levels of abrasion for the surface being worked on. Wheel blasting is ideal for automotive transmission parts such as shafts and gears. In most cases, it is used to process high-intensity value specifications on large surfaces. The even distribution of metal shots makes this equipment suitable for processing large quantities of smaller components at once.

- Air blasting equipment – This equipment uses pressurized air to propel metal shots onto the surface being worked on. The air is supplied from compressors and directed on the metal shots through a strong-walled nozzle. Airblast equipment is further classified into gravity suction, direct pressure, and blower types. Air blasting is considered cost-effective and environmentally friendly. The metal shots are collected and recirculated while working on the surface. A suction force is used to separate the metal shots from dust inside the dust collector. This prevents dust matter from being recirculated as part of the propellant as it could reduce the efficiency of the equipment. Air blasting is used to remove rust and create a desired finish on surfaces. The uneven and controlled propelling of metal shots makes air blasting ideal for polishing fragile and sensitive objects.

Shot blasting is applied in many industries. One of its applications is in the ship construction sector, where it is used to remove rust on the surface of ships for repainting. Maintenance of mechanical parts in vehicles is done by wheel blasting. This form of shot-blasting removes contaminants on the surface, making the parts more efficient. Having the right purpose for shot blaster equipment doesn’t guarantee that you get the best on the market.

What Makes A Good Shot Blaster Equipment?

The presence of many brands on the market makes it hard to find the best shot blaster equipment for your needs. There are several factors that could be used to distinguish a good short blaster from the rest. These qualities determine how valuable the equipment will be throughout its active usage period. They include;

- Cost of the equipment -Financial consideration is essential in making industrial equipment purchases. The cost of shot blast equipment should be affordable to avoid financial constraints, which in turn slow productivity. The cost of equipment is relative to the amount of work it is supposed to deliver. If the needed work is for a short while, one can hire the equipment instead of buying one. The cost of installation should be within your budget. Some shot blasters require technical skills when installing in your workplace. Paying many technicians to install the equipment increases its costs.

- Working capacity – Workload is one of the main considerations you should make when procuring a shot blaster. It guides you on the capacity of the blaster you need to buy. A good shot blaster should deliver the most within a very short time. The blaster should provide consistent output even when used over long hours. If the items to be blasted are large, you need a blaster that can cover a larger surface at once.

- Maintenance costs – Initial acquisition is not the only expense you might incur when buying a shot blaster. Several other expenses arise during the working period of the equipment. For instance, you need technicians to operate the blaster. Complex blasters require technical skills to operate. This implies that you spend a lot more on labor. Modern blasters have computerized systems that minimize the number of technicians needed for their operation. Repairs and replacements are other forms of maintenance costs. The shot blaster you purchase should be durable enough to minimize repairs and replacement costs. The blaster’s power consumption should be within a manageable range. Power is one of the high expenses incurred by industries. When purchasing a shot blaster equipment, you should ensure it has a low power consumption rate for environmental conservation and financial stability.

- Suitability of the equipment – Shot blaster equipment is made for different purposes. The equipment you buy should be suited for your needs. For instance, blasting delicate surfaces require air shot blasters. The environment within which the equipment works should also guide you when selecting the best blaster. If space is limited, blasters with many external accessories might not be ideal. Air blasters have a filtering mechanism which makes them ideal in areas with a lot of dust.

There are many other factors you should consider when selecting shot blaster equipment. Consulting experts in the industry will give you a clear picture of what to expect from the equipment you buy. Proper maintenance is encouraged to increase the equipment’s working life. Cleaning after use and oiling of moving parts improves the efficiency of the equipment. The equipment needs to be used for the right purpose to deliver the best results.