If you are thinking about buying a used press brake machine, there are some really important things that you have to consider and remember when looking at your options. Naturally, the very first thing you’ll have to do is choose the type that’ll suit your needs, nonetheless, when buying a used machine, this is the simplest thing to determine and do.

Now, this might make you wonder – what are the other things that I have to keep in mind when searching for such a device? Luckily for all individuals looking for an answer to this question, this article might help. Let’s take a look at the list of 5 things you must consider before buying a used press brake machine:

1. Inspect The Overall State And Condition

Before you do anything else from this list, it is important for you to examine the overall state and condition of the parts. Why? Well, if you do not do this, you might end up paying a lot for the repairs, which means that the expenses you have will be more than you initially planned on spending.

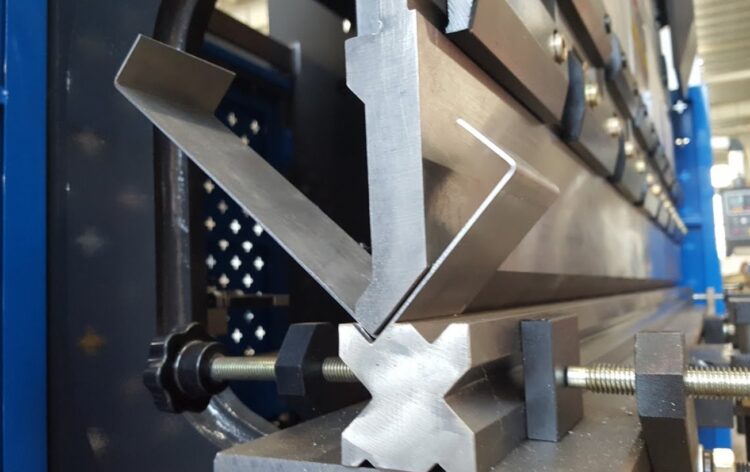

Hence, the first thing you should do is check whether the ram and bed show signs of damage such as gouging, deformation, and so on. The tool holders are also important to look at and a lot of the machines come with removable tool holders. Again, see if there is any damage to said components.

The hydraulic system and cylinders should be inspected as well, which means that you must see if there are any leaks. In most cases, you’ll see the cylinders on the front of the device. If there are any leaks, know that it can cost a lot to replace or repair the parts, hence, you might want to skip buying a press brake machine that shows signs of leakage.

2. Verify if The Control System Functions Properly

If it is equipped, you should check how bright the screen is. Although outdated, a CRT screen can still be used for a lot of years, and it could even be upgraded with the newest LCD technology – but, this will depend on the make and model of the device. Additionally, you should verify with the manufacturer about the support for the control system.

Most commonly, you’ll find that the more generic it is, the longer there will be support for the components and services. On the other hand, with other machines, the serviceability might only be available for some time before it stops, which means that you might not easily find the components you need in the future.

3. The Tool Holders

According to a press brake manufacturing company shenchong.com, you must inspect the tool holders for any wear and tear. Why?

Well, for starters, it can save you a lot of trouble later on because it will prevent you from losing parts and tools that can be costly, and also, if you do not examine it, you might not be able to utilize it for long.

So, when examining the holders – if they’re included in the offer – you should see if there are dents, cracks, scratches, and also check if they are deformed. It’s common for these pieces to be damaged, however, you should still be able to utilize it. In most cases, the holders can be removed, which implies that you can choose not to purchase them with the device if they are too damaged.

4. The Manufacturing Date

As we mentioned earlier in the article, if the press brake was properly maintained, it can be used for several more years. However, we also mentioned that some of them cannot be serviced anymore, which means that it’ll be increasingly difficult for you to obtain the components that need to be replaced.

So, if the hydraulic/mechanical device is manually operated without a CNC controller, its lifetime can go over fifty years from the day it was manufactured, but, if it is CNC controlled and older than twenty years, it will be difficult for you to find the parts you need or service it when the time comes.

This is why you must learn when it was manufactured. By doing so, you won’t only ensure that you can use it for a long time, but, you’ll also be able to avoid expensive repairs and you won’t need to endlessly search for used parts that you can use for your press brake machine.

5. It Must Be Safe For Use

Last on our list, but not least important is the safety of the device. You’ll want to guarantee that it meets all the safety regulations and requirements of your shop, as well as the OSHA regulations. In order to make it safer, you can always choose to purchase additional safety parts.

Which safety parts can you buy? Well, you can add light curtains, safety mats, fencing, and so on. Of course, you’ll need to pay extra for these items, but since you are buying a used machine, you’ll still be paying less than you would if you chose to purchase a new one.

Bonus Tip – Read The Reviews

One of the things that a lot of people fail to do is to check the reviews of other users. No matter if they are for a new machine or a used one, you must ensure that it functions well. This is why you’ll want to do some digging online and see whether or not it’ll suit your needs and requirements.

Conclusion

As you can see, there is a wide range of things that you have to consider before choosing a specific used press brake machine. However, by doing so, you’ll ensure that you chose a device that will suit your needs, but more importantly, you’ll ensure that you can use it for years.

So, now that you are aware of all the things you need to check and determine when looking at your options, you might not want to lose any more of your time. Instead, you should open up your browser and start searching for a press brake machine that will suit your needs and budget.

![3 Table Saw Cheapest Price: Reviews & Top Choices [2024 Updated]](https://www.fotoolog.com/wp-content/uploads/2021/09/Table-Saw-Cheapest-Price-218x150.jpg)