With its appearance on the market, plastic has replaced some much more expensive materials in many branches of industry. Due to the ease of shaping and far more favorable prices – plastic is widely used today. Of course, to make any plastic product – we must include the preparation work. It involves making a mold for the shape we want to make and which we will use for mass production.

Today, the so-called injection molding method is especially effective. What exactly is injection molding and what are its advantages – find out in this text.

Molding And Injection Molding

Today we can hardly imagine life without plastic. It is almost all around us. It is used in all spheres of life, and plastic parts make up elements of the things we use every day. With its appearance on the market, plastic has replaced some much more expensive materials in many branches of industry. Due to the ease of shaping and far more favorable prices – plastic is widely used today.

In addition to various companies that have their production and already designed molds – there is a growing number of larger companies that use injection molding. It is much more efficient today and switches quickly from one form to another.

What Is Injection Molding

The application of plastics in the industry has been very diversified for many years. The most important part of this use refers to the elements that are made by the injection process. The growing use of plastics requires greater responsibilities from designers and engineers, both in terms of construction precision – and in terms of the size of tools for precision mold making.

Mold is one of the most important factors that directly affect the shaping of plastic mass into a product of the desired dimensions. It helps to achieve a smooth structure and surface quality. Therefore, the correct construction of the mold is a very responsible task of the constructor. It consists of solving some problems in thermo-dynamic processes. However, the quality of the products themselves depends on many other things such as the quality of the plastic mass, the desired shape, factory conditions, and mold production procedures.

Advantages Of Injection Molding

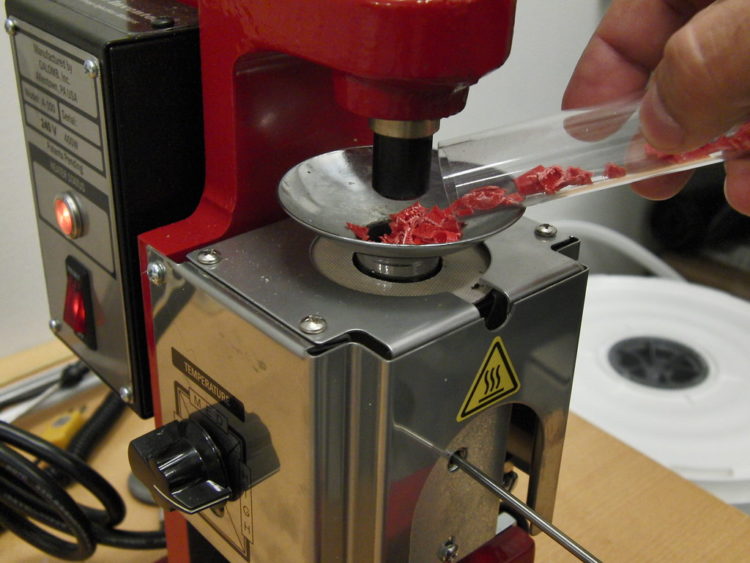

Injection molding of plastic is a simple procedure that is proceeding cyclic. It consists of molding a plastic mass of the required certain viscosity – and its injection into a mold cavity which is heated to a certain temperature. The product, formed in the mold by injection molding, becomes suitable for extraction from the mold cavity by polyreaction and cooling.

Injection molding can be automated and is good for producing more complicated and stable product dimensions. For something like this, you need an injection mold but also other equipment.

This equipment contributes to the quality and choice of materials of the product itself, including transport. Injection molding must fulfill its given functions. These include preparing the plastic mass, injecting it, creating a certain shape at a certain temperature, etc. Companies such as Metal Pie have recognized the great advantages of injection molding.

Today, these and similar companies provide their products and services to customers around the world. This is not surprising since the customers’ need is growing – and therefore, the market demand for this type of service that is a necessary link in the mass production chain is growing as well.

Injection Molding Procedure

The basic task of injection molding of the plastic mass of a given shape during one cycle. We can say that injection molding is a required process because due to the speed of the bolts and rollers – a very high level of pressure needs to be achieved. For injection molding, the plastic should maintain a certain temperature. The injection molding process requires a high molding temperature.

Therefore, the cooling water should be cold to remove the heat from the mold. This way, the cold water machine requires more cooling energy and a lower temperature – but we can achieve a status suitable for injection molding.

Where Injection Molding Is Used

Injection molding is mostly used in the manufacture of equipment and parts for power supplies, medical devices, and electronics industry. However, they are widely used in automotive industries, but also in other industries almost equally. Specially designed injection molds can be used to save manufacturing costs for all consumers who want to enter the production of plastic products.

There is also the possibility of making thermoplastic injection molds such as 2K injection molds, unscrewed molds, multi-cavity molds, multi-action molds, etc. This type of service to potential customers greatly reduces additional costs – because you can immediately install the molds and start production.

Who To Contact For Mold Production?

The largest manufacturers of plastic molds and injection molding are mostly large companies many of which come from China. They can very quickly and efficiently help you with any questions or work with injection molds for different purposes and in different industries. It is up to you to decide on one of the options if you are engaged in the production of plastic products.

The advantages of companies that deal with injection molding and making custom molds are not only in serial production – but also help with mold design, assembly, and other various tips if needed. Certainly, this type of service also affects successful production because you will use the services of one company and have full cooperation.

Conclusion

From all this, we could see the importance of plastic materials and their use in mass production. Certainly, the material is not the only thing that is necessary for such a production. For the production of plastic parts to run smoothly – the molding of plastic is of utmost importance. Therefore, specialized companies for the production and molding of plastic materials are a great ally in this business.

If you intend to engage in the production of plastic products, which is a lucrative business today – hire a proven company. You should opt for one that has been with you from the beginning – and that will help you grow faster.